In This Article

Share

Employee Spotlight: Kunjan Patel

Meet Kunjan Patel, a key team member at Richter Lighting Technologies GmbH since 2019. With a background in mechanical and polymer engineering, Kunjan has played a pivotal role in advancing the company’s 3D printing operations, applying his skills to a wide array of innovative projects, including a landmark initiative in Malaysia.

In this insightful interview, we delve into his experiences, his growth in the company, and his view of the 3D printing landscape.

Can you briefly Introduce your self?

Greetings. I’m Kunjan Patel, hailing from India. With a strong foundation in mechanical and polymer engineering, I have a profound enthusiasm for emerging technologies that enable us to accomplish tasks once deemed resource-intensive.

How did you find out about Richter?

My journey with Richter began during an industrial excursion upon completing my master’s degree in Aalen University in 2019. Bernd, our CEO, introduced me to the super interesting projects the company was engaged in. It got me moved and since that day, I am working here!

What do you do here? Can you briefly describe your role and how it involves 3d printing?

My role centers around the digitalization of various manufacturing technologies, with a notable focus on 3D printing. I manage the company’s 3D printing operations, which includes various aspects ranging from technologies, materials, design guidelines, process validation, testing and ensuring the final product meets quality standards.

What types of materials do you primarily work with in 3D printing for architectural applications?

Our primary focus in 3D printing for architectural applications revolves around engineering plastics. These materials are selected for their ability to withstand elevated temperatures, possess exceptional strength, deliver appropriate fire performance, exhibit weather resistance, and are deemed reliable for various functional applications.

With regards to tools, we employ a range of tools and technologies such as design software, structural simulation (Finite Element Method), high temperature 3D printers and 3D scanning.

Can you describe a recent project where 3D printing made a significant impact?

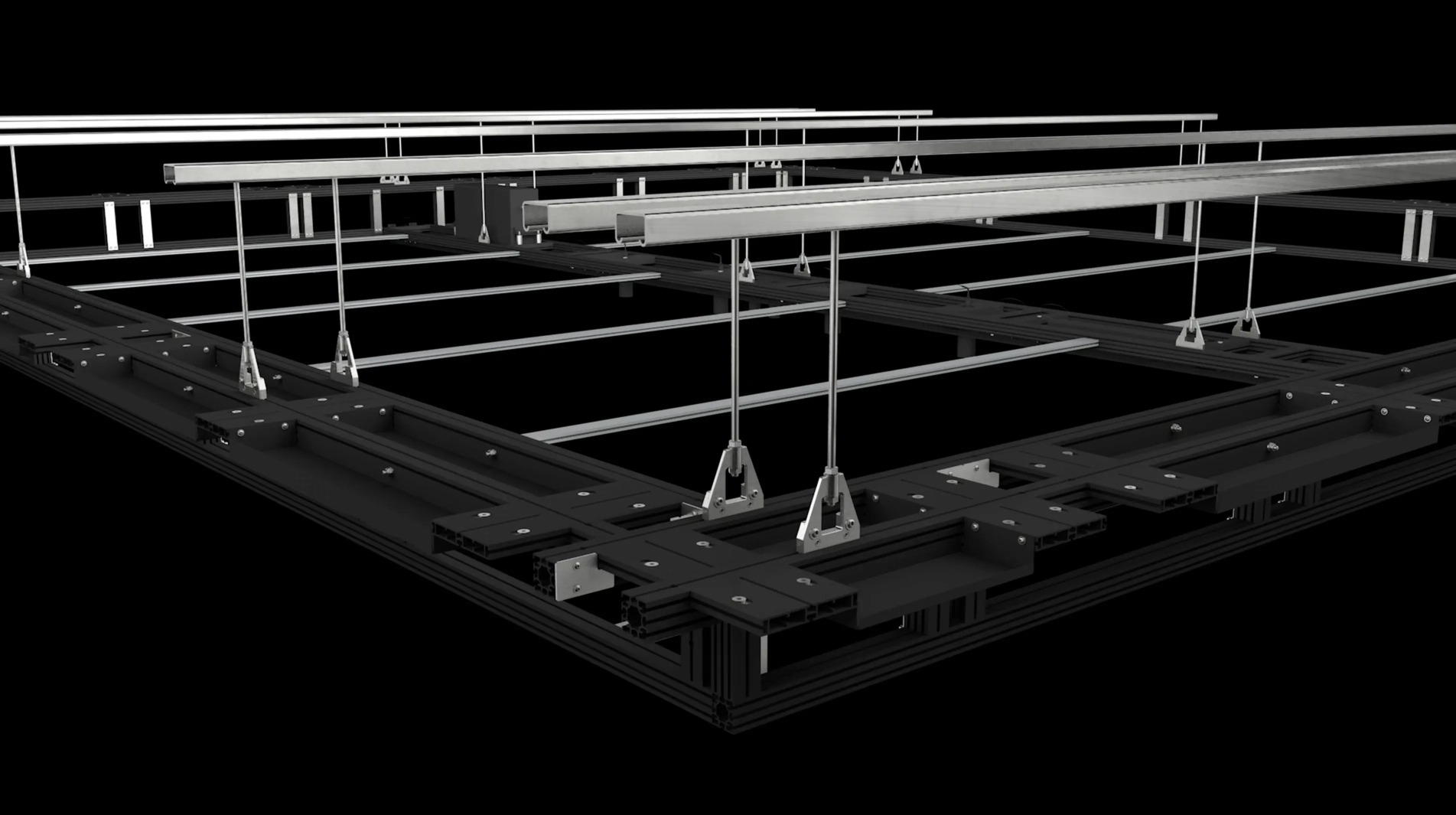

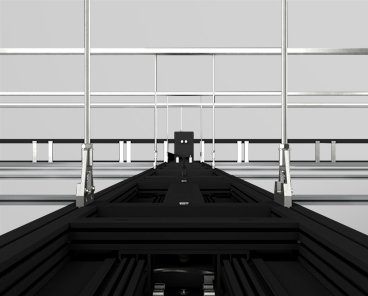

At present, we’re actively engaged in an architectural landmark project located in Malaysia. In this project, we’ve used 3D printing to manufacture architectural connectors for a fabric holding system, showcasing the technology’s pivotal role in this project’s success.

This project also involves collaboration extending to various cross-functional teams, as 3D printing inherently requires adherence to the Design for Manufacturing principles. This often leads to design modifications, necessitating close involvement and coordination with architects, engineers, and projectmanagers.

What sets this workplace apart in a unique way?

What truly makes our workplace stand out is its dynamic nature. Every day brings fresh challenges and new opportunities. We foster an open work environment where everyone is accessible. Moreover, our strong connections with various industries provide us with valuable insights that set us apart.

What’s the most rewarding aspect of your job?

The most gratifying aspect of my job is the sense of fulfillment that comes from addressing challenges using cutting-edge technologies.

It has also shaped my professional growth akin to a child discovering a new perspective on the world. I’ve been encouraged to question industry-standard practices at every stage and seek unique alternatives that create new opportunities, rather than adhering to convention.

What advice do you have for people looking to get into the field of 3D printing, particularly in architecture and construction?

My advice for those aspiring to enter the field of 3D printing, especially in architecture and construction, is to get creative, focus on addressing broader challenges that traditional manufacturing methods face. Always keep an eye out for innovative approaches and advancements to harness the full potential of this technology.

Final question:

If you could 3D print anything in the world, just for fun, what would it be and why?

If I could 3D print anything, and not just for fun, I’d pick a functional rocket engine. It’s an incredibly stressed mechanical part that’s responsible for overcoming gravity’s pull. The potential for innovative design and the challenge of ensuring its safe 3D printing would make it an super cool and reassuring accomplishment.

Are you interested in building a fulfilling career with us at Richter?

Then visit our career page.

In This Article

- Can you briefly Introduce your self?

- How did you find out about Richter?

- What do you do here? Can you briefly describe your role and how it involves 3d printing?

- What types of materials do you primarily work with in 3D printing for architectural applications?

- Can you describe a recent project where 3D printing made a significant impact?

- What sets this workplace apart in a unique way?

- What’s the most rewarding aspect of your job?

- What advice do you have for people looking to get into the field of 3D printing, particularly in architecture and construction?

- Final question: If you could 3D print anything in the world, just for fun, what would it be and why?

- Are you interested in building a fulfilling career with us at Richter?

Share